Main configuration

1. Program controller (PLC): Siemens, Germany.

2. Man machine interface: German Siemens 7-inch color touch screen.

3. Photoelectric sensor: Leuze, Germany.

4. Relay and air switch: Schneider, Germany.

5. Frequency converter: Siemens, Germany.

6. Labeling motor and its driver: Shenzhen JMC hybrid closed-loop stepping motor and its driver, (or 750W German Siemens Servo motor and its driver are optional)..

7. Conveyor belt motor: 750W Taiwan Yongkun frequency conversion AC motor.

8. Entrainment motor: 140W domestic variable frequency AC motor.

9. Bottle splitting motor: 60W domestic AC motor.

10. Conveyor belt: 114.2 wide POM chain plate.

11. Exposed parts: 304# stainless steel, anodized aluminum alloy, electroplated 45# steel, engineering plastic parts.

Machine Feature

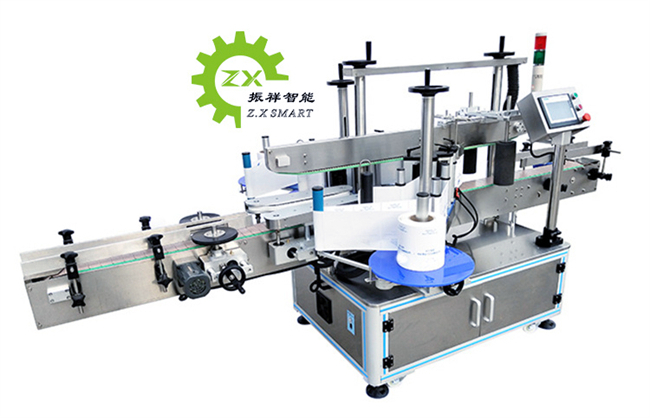

1.The machine frame is manufactured of 304 stainless steel, aluminum alloy through the light surface angle, positive polarization, engineering plastics(chain plate), etc., which meets the requirements for GMP use.

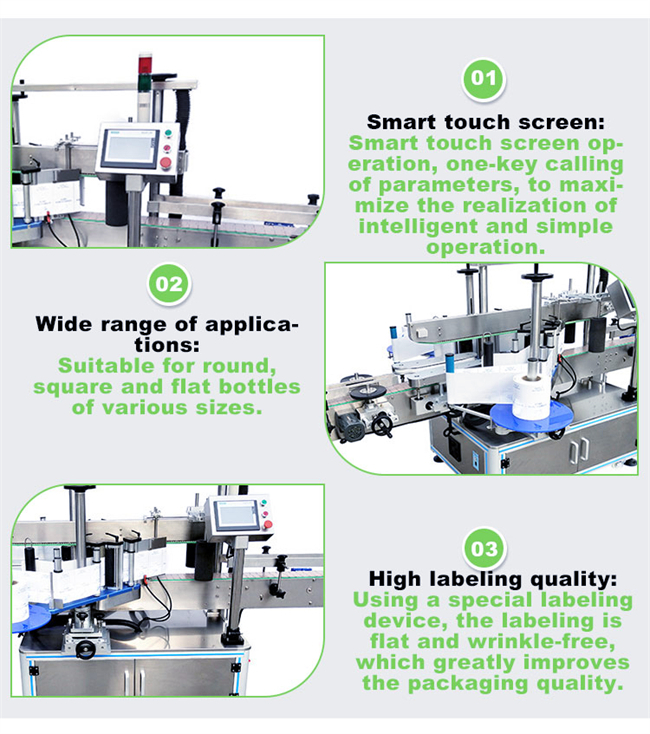

2. Multiple groups of labeling parameters memory, can quickly replace the production of products.

3.The mechanical structure of the whole machine adopts a rigid design, which is simple and stable.

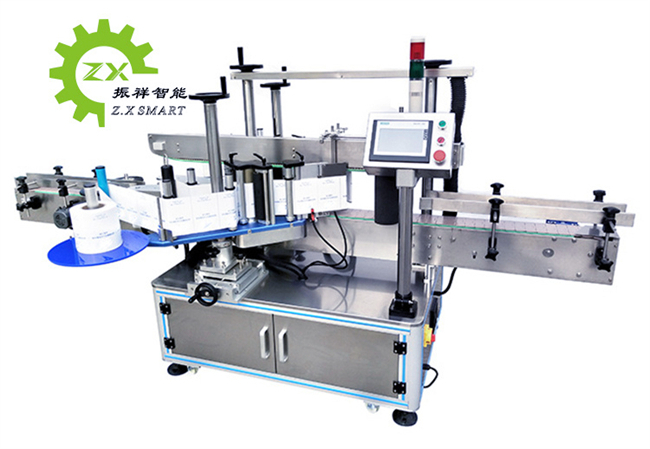

4.The scraper is equipped with the machine adopts a sponge spring steel plate combination, a brush, and a pressure adopts a combination of non-powered sponge rolls to ensure that the label is free of bubbles and can be quickly disassembled to accommodate different sizes of labels.